- Home

- About Us

- History

- PO Requirements

- Capabilities

- CNC H/V Milling • Boring Mills • Jig Boring • CNC Jig Boring

- Lathes • Vertical Turret Lathes

- Lapping & Grinding • OD & ID Grinding • Honing

- Welding • Large Fabrication • Confined Space Welding

- EDM • Water Jet

- De-Burring • Aqueous Cleaning

- Non-Destructive Testing

- Inspection

- Programming

- Assembly • Work Cells

- Patented Torque Equipment

- Equipment Lists

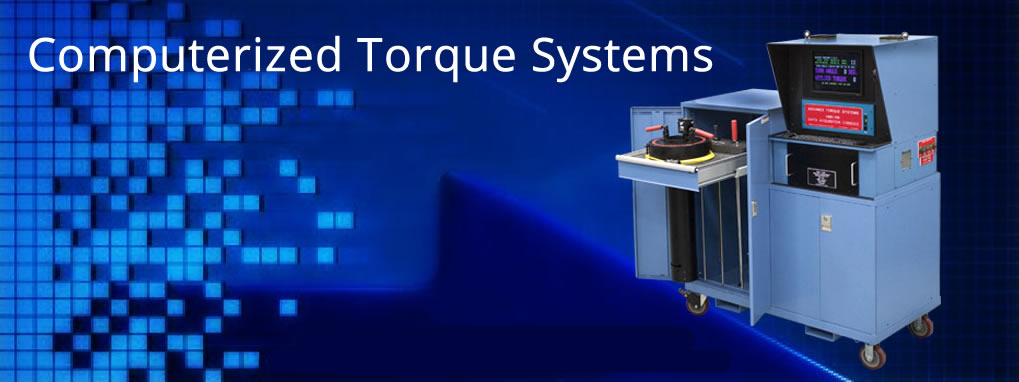

In 1987, Advance Mfg. Co., Inc. developed the first computerized torque systems to integrate precision tooling on a complex assembly procedure for the world’s leading manufacturers of jet engines.

With the software managing the process, the need for a dedicated quality person to validate the steps typically required for torquing hidden fasteners is eliminated. A remote calibration stand determines the mechanical efficiency of the wrench system and confirms the accuracy and repeatability of the nut angle encoder.

The system meets objectives of engineers and process planners to achieve an effective tool for creating a bolted joint that has consistent clamp characteristics, thus greatly reducing engine vibration.

We have also created systems for blind torquing of bolts in aircraft engine compressor rotor drums. These systems are currently in service on many high thrust jet engines in both military and commercial applications.